Glass drink beverage water dispenser

Short Description

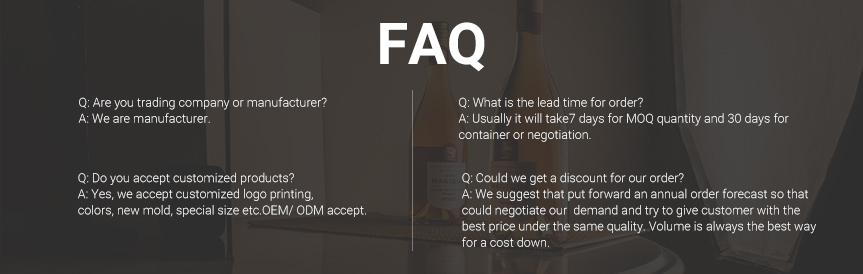

JUMP is a professional glass ware manufacturer with 20 years experience. Specializing in production of various glass bottles & glass jars. Covers an area of 50000 m² and counts more than 500 employees, produce capacity is 800 million pcs per year. With advanced technical support jump have export glass bottles and glass jars to Europe ˴ United States ˴ South America ˴ South Africa ˴ Southeast Asia ˴ Russia ˴ Central Asia and the Middle East market, where enjoys a good reputation. Also have branches in Myanmar ˴ Philippines ˴ Russia ˴ Uzbekistan. Professional design team provide personality service for customers. Committed to providing safe ˴ professional ˴ standardized ˴ efficient one-stop glass packaging services for customers.

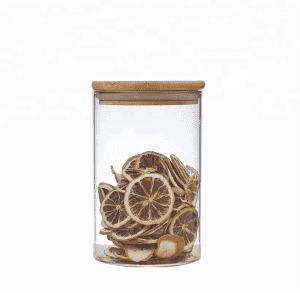

Product picture

Technical Parameters

| Product name | food grade High Borosilicate Glass drink beverage water dispenser |

| Color | Transparent, clear or customized |

| Capacity | 100ml 150ml 250ml 500ml 750ml 1000ml or customized |

| Sealing type | Screw cap, bamboo lid or cork or customized |

| MOQ | (1) 2000 pcs if stocked |

| (2)20,000 pcs in bulk production or make new mould | |

| Delivery time | (1) In stock : 7days after the advance payment |

| (2) Out of stock : 30 days after the advance payment or negotiation | |

| Usage | Food or other |

| Our advantage | Nice quality, professional service,fast delivery, competitive price |

| OEM/ODM | Welcome,we could produce mold for you. |

| Samples | Provided |

| Surface treatment | Screen printing ˴ roasting ˴ printing ˴ sandblasting ˴ carving ˴ electroplating and color spraying decal ˴ decal , etc. |

| Packaging | Standard safety export carton or pallet or customized. |

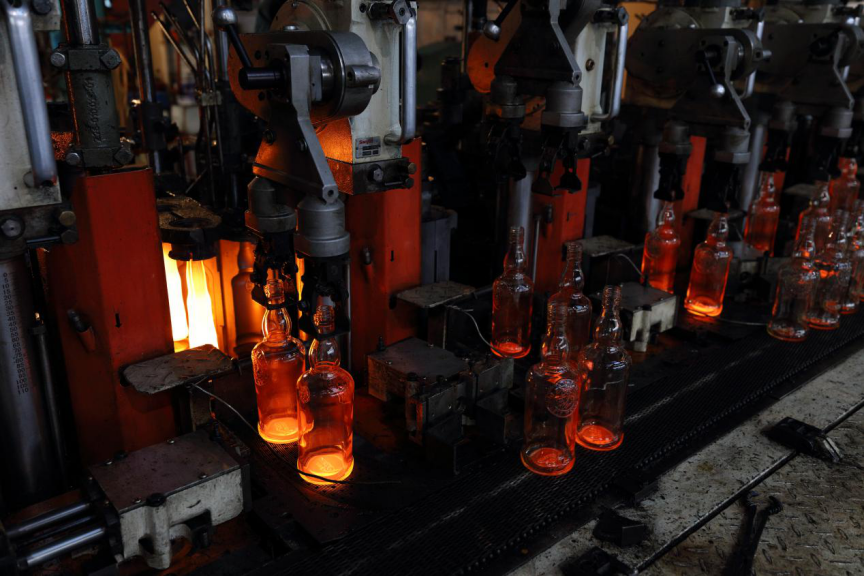

Production Process

Write your message here and send it to us