The shape and structure design of glass container

Before starting to design glass products, it is necessary to study or determine the full volume, weight, tolerance (dimensional tolerance, volume tolerance, weight tolerance) and shape of the product.

1 The shape design of the glass container

The shape of the glass packaging container is mainly based on the bottle body. The molding process of the bottle is complex and changeable, and it is also the container with the most changes in shape. To design a new bottle container, the shape design is mainly carried out through the changes of lines and surfaces, using the addition and subtraction of lines and surfaces, changes in length, size, direction, and angle, and the contrast between straight lines and curves, and planes and curved surfaces produce a moderate texture sense and form.

The container shape of the bottle is divided into six parts: mouth, neck, shoulder, body, root and bottom. Any change in the shape and line of these six parts will change the shape. To design a bottle shape with both individuality and beautiful shape, it is necessary to master and study the changing methods of the line shape and surface shape of these six parts.

Through the changes of lines and surfaces, using the addition and subtraction of lines and surfaces, changes in length, size, direction, and angle, the contrast between straight lines and curves, planes and curved surfaces produces a moderate sense of texture and formal beauty.

⑴ Bottle mouth

The mouth of the bottle, on the top of the bottle and can, should not only meet the requirements of filling, pouring and taking of the contents, but also meet the requirements of the container’s cap.

There are three forms of sealing the bottle mouth: one is a top seal, such as a crown cap seal, which is sealed with pressure; the other is a screw cap (thread or lug) to seal the sealing surface on the top of the smooth surface . For wide mouth and narrow neck bottles. The second is side sealing, the sealing surface is located on the side of the bottle cap, and the bottle cap is pressed to seal the contents. It is used in jars in the food industry. The third is the sealing in the bottle mouth, such as sealing with cork, the sealing is done in the bottle mouth, and it is suitable for narrow-neck bottles.

Generally speaking, large batches of products such as beer bottles, soda bottles, seasoning bottles, infusion bottles, etc. need to be matched by cap-making companies due to their large volume. Therefore, the degree of standardization is high, and the country has formulated a series of bottle mouth standards. Therefore, it must be followed in the design. However, some products, such as high-end liquor bottles, cosmetic bottles, and perfume bottles, contain more personalized items, and the amount is correspondingly small, so the bottle cap and the bottle mouth should be designed together.

① Crown-shaped bottle mouth

The mouth of the bottle to accept the crown cap.

It is mostly used for various bottles such as beer and refreshing beverages that no longer need to be sealed after unsealing.

The national crown-shaped bottle mouth has formulated recommended standards: “GB/T37855-201926H126 Crown-shaped bottle mouth” and “GB/T37856-201926H180 Crown-shaped bottle mouth”.

See Figure 6-1 for the names of the parts of the crown-shaped bottle mouth. The dimensions of the H260 crown-shaped bottle mouth are shown in :

② Threaded bottle mouth

Suitable for those foods that do not require heat treatment after sealing. Bottles that need to be opened and capped frequently without having to use an opener. Threaded bottle mouths are divided into single-headed screwed bottle mouths, multi-headed interrupted screwed bottle mouths and anti-theft screwed bottle mouths according to the requirements of use. The national standard for screw bottle mouth is “GB/T17449-1998 Glass Container Screw Bottle Mouth”. According to the shape of the thread, the threaded bottle mouth can be divided into:

a Anti-theft threaded glass bottle mouth The threaded glass bottle mouth of the bottle cap needs to be twisted off before opening.

The anti-theft threaded bottle mouth is adapted to the structure of the anti-theft bottle cap. The convex ring or locking groove of the bottle cap skirt lock is added to the structure of the threaded bottle mouth. Its function is to restrain the threaded bottle cap along the axis when the threaded bottle cap is unscrewed Move up to force the twist-off wire on the cap skirt to disconnect and unscrew the threaded cap. This kind of bottle mouth can be divided into: standard type, deep mouth type, ultra-deep mouth type, and each type can be divided.

Cassette

This is a bottle mouth that can be sealed by axial pressing of external force without the need for professional packaging equipment during the assembly process. Cassette glass container for wine.

stopper

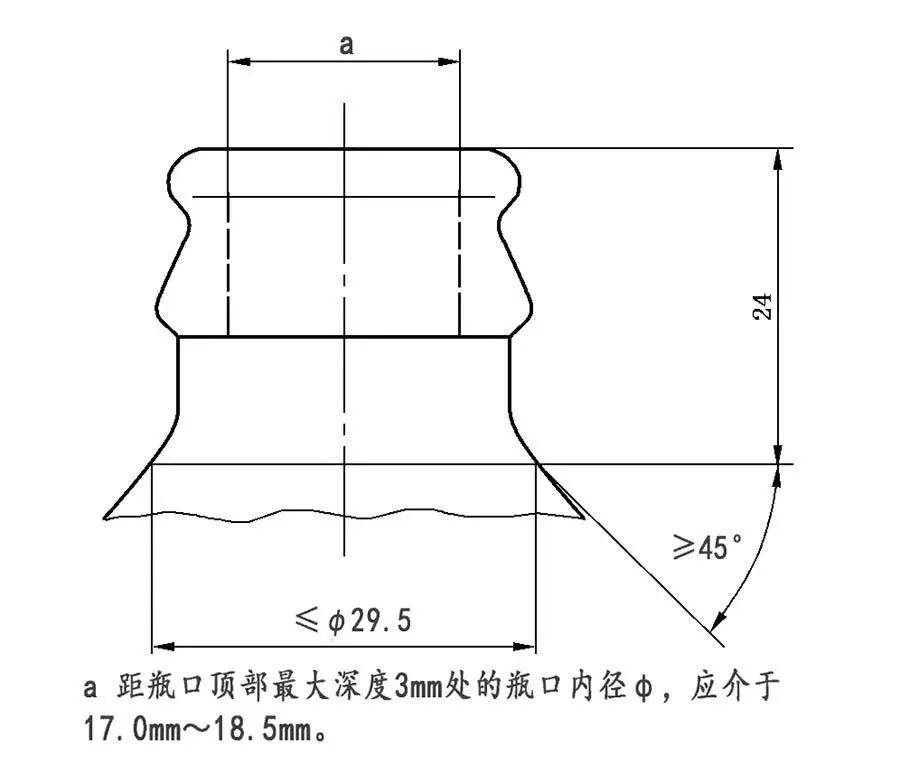

This kind of bottle mouth is to press the bottle cork with a certain tightness into the bottle mouth, and rely on the extrusion and friction of the bottle cork and the inner surface of the bottle mouth to fix and seal the bottle mouth. The plug seal is only suitable for the small-mouth cylindrical bottle mouth, and the inner diameter of the bottle mouth is required to be a straight cylinder with sufficient bonding length. High-end wine bottles mostly use this kind of bottle mouth, and the stoppers used to seal the bottle mouth are mostly cork stoppers, plastic stoppers, etc.Most bottles with this type of closure have the mouth covered with metal or plastic foil, sometimes impregnated with special sparkling paint. This foil ensures the original state of the contents and sometimes prevents air from penetrating into the bottle through the porous stopper.

Post time: Apr-09-2022